Projects

Farallon Consulting provides a diversity of environmental consulting services to clients throughout the west coast and beyond with offices in Washington, Oregon, and California.

Sediment Removal and Bioremediation Reactive Wall at Mare Island

Following a feasibility study that identified the best solution to remediate the concerns, Farallon conducted a pilot study to test the...

View Project

In-Situ and Ex-Situ Remediation Services at Former Mine

Farallon worked with multiple oversight agencies to characterize an off-site hydrocarbon plume that impacted an adjacent water body,...

View Project

Construction Support Services for Hospital Expansion

Asbestos dust monitoring was required for construction of the building to keep the project in compliance with the San Francisco Health...

View Project

Farallon Volatile Organic Compound Monitoring Probe

Farallon was retained by a property owner to install the patented Farallon VOC Monitoring Probe and conduct sampling at a dry cleaning...

View Project

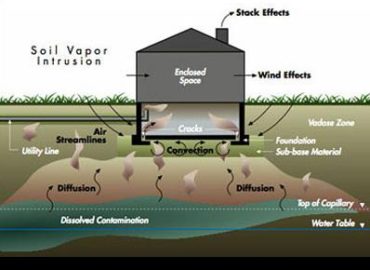

Fast-Track Vapor Intrusion Mitigation Regulatory Agreement

Farallon was engaged to perform environmental due diligence at a warehouse formerly used for industrial manufacturing. During the Phase I...

View Project

Manufacturing Plant

Farallon was contracted for technical support by an insurance carrier covering the investigation and cleanup of a widespread groundwater...

View Project

Protection from Methane Gas Infiltration

Farallon designed a methane gas mitigation system to protect a large retail warehouse located over layers of methane-generating organic...

View Project

Trichloroethene Release Triggers Vapor Intrusion Investigations, Mitigation Measures

Urban areas across the United States have long been centers of industry, and often become the focus of environmental investigations when...

View Project

Stormwater Discharge System Source Control Evaluation

The NPDES and the state of Oregon 1200-Z Industrial Stormwater General Permit require monitoring of stormwater discharges from the site....

View Project

Farallon Devises Shorter Route to No Further Action Determinations

When another consultant recommended costly subsurface investigations to support a request for regulatory closure, the property owners...

View Project

Former Food Processing Facility

Farallon managed the cleanup action at a former large food processing facility in Seattle, Washington. Prior to the cleanup, Farallon...

View Project

Fort Lewis Tank Program

Farallon collaborated with a general contractor/construction management firm at the Fort Lewis U.S. Army Post to close and replace over...

View Project

Farallon Consulting and our team of experts are active members of professional associations.